It'd be hard to justify the investment in my 3D printer for the practicality of the items I have made. The parts I printed for securing by drone's propellers during travel being a lone exception. That is not the point though. My Flashforge Adventurer 3 is a relatively cheap, but geeky, way to introduce myself to the technology. I don't know which I find more amazing: the hardware or the software!

First, being able to accurately shoot a thick fishline of corn-based plastic through a 0.4 mm glue gun at around 400°F sounds pretty sophisticated. Then, the fact the bed and nozzle are accurate enough to create an object out of thin air is pretty amazing too. This isn't a typical creation where one starts with a block of material and whittles away until it becomes the object. Rather, the process starts by adding layer upon layer of material to nothing.

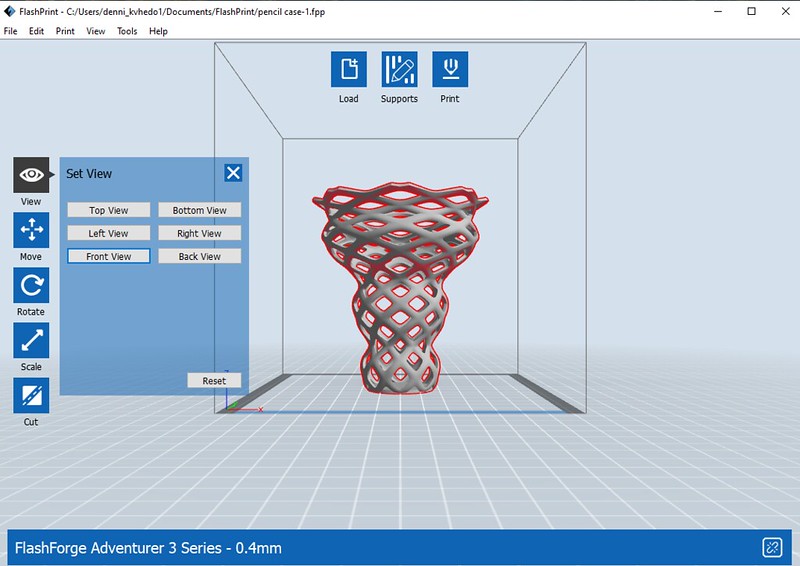

However, without software, the physical components could do nothing. I load a 3-D project file on a tiny application on my PC and the software figuratively slices an object into minuscule layers from the bottom up. Then, it creates a file for the printer so the information that can direct the nozzle to apply the hot plastic to the right place at the right time, in the right order.

The implications boggle. In the future, when the tech is more advanced, people may not have to buy certain items at a store. They will, instead, be able to order only the plans or even download public domain copies. Many simple objects could simply be created directly by an end-user. Imagine how that could affect transportation, distribution, warehousing, and retail!