I am interested in testing out my new 3D printer. I found a rather complex object for a trial print. Many 3D objects are saved as .stl CAD files. There are a lot of websites to help both hobbyists and professionals.

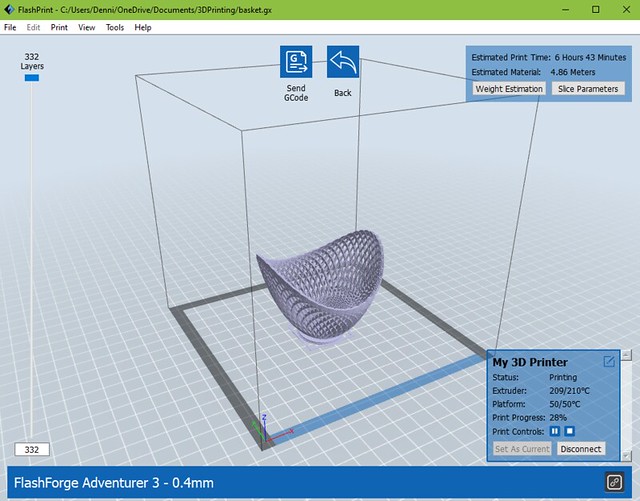

I located a basket and opened it in FlashPrint, the software that came with my Flashforge printer. I resized so it was considerably smaller. The program 'slices' an object into horizonal layers. The printhead then starts at the base and extrudes plastic through a nozzle layer-by-layer. It obviously can work with very small tolerances.

As a print is created, it is fun and interesting to watch its progress. It takes a long time to do a detailed print. For example, this small basket took over six hours! During the print, I also watched via my PC because there is a small camera built inside my Adventurer 3.

This process is such a new and different way of creating an object. Throughout history, in most cases, artisans have traditionally taken a large block of something and gotten rid of material until the object was formed. Here though, we started with just a spool of plastic wire and built something by only adding material.

Owing to the way they are created, some 3D objects must be positioned uniquely so that the layers can added from bottom to top. I wanted to see how this PLA type of natural plastic would work with a smaller base and sides that grow increasingly wider. As you can see by looking below, it worked well. PLA is made from materials such as corn and sugarcane and is biodegradable. My printer can use other types of plastic as well. I'm going to enjoy playing and learning about this topic.